Services to Fit Your Needs

As experts in formulating wax blends, Blended Waxes has many services available that will help you get the custom wax you need at the quality you expect. View each Service Page to learn about each service or contact us for more information.

Custom Blending Solutions

Our targeted solutions enable companies in industry sectors like medical, cosmetics, art and packaging to receive a precise wax blend that meets their unique performance and texture specifications. These blends provide the flexibility to experiment with various ingredients or create a new wax product.

The custom blending services at Blended Waxes help you develop a product that meets your customers’ demands and increases their satisfaction level. Our solutions can also contribute to lower production costs by utilizing less expensive ingredients and increasing manufacturing efficiency. In addition, we offer more eco-friendly wax ingredients that can lead to a cleaner-burning product.

Toll Manufacturing

As a full-service toll manufacturing company, Blended Waxes can handle most or all of your wax production processes. As a result, you can focus more time and resources on other essential business areas.

Our team will oversee every aspect of the wax process, including blending, production and packaging. You’ll benefit from our state-of-the-art, high-tech industrial equipment and years of wax blending expertise, which enable us to provide a high-quality product that fits your time frame and budget.

Our modern facility contains advanced equipment for storing and blending substantial wax quantities, and our in-house professional lab technicians have the expertise to manufacture and test the products to ensure they meet your specifications. You can even choose the appropriately sized storage option to accommodate your items.

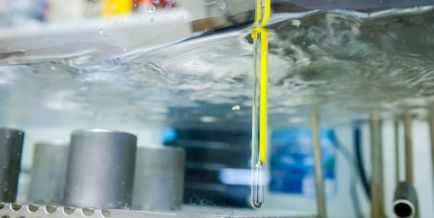

Lab Testing

Our custom blended waxes services include laboratory testing that benefits from our proven quality control methodologies to ensure maximum wax precision and quality. We utilize the most advanced lab equipment and data technology to control the sample’s quality, consistency, color and content, helping to produce high-performing wax blends that exceed your expectations.

Bulk Storage and Order Fulfillment

Blended Waxes can help your company resolve its storage issues. We have the off-site and on-site capacity to store raw materials, packaged goods and other items. This service enables you to reach your markets across the U.S., as we can ship your goods to your facility or directly to your customers as needed from our central Midwest location.

The benefits of our bulk storage solutions include gaining additional storage capacity while freeing up extra space at your facility. You’ll also experience reduced operating costs, safer product storage and a more efficient supply chain.

Private Label Manufacturing

Our commitment to being a custom blend wax manufacturer extends to our labeling solutions. We’ll provide a product featuring your company’s name and branding that meets your exact specifications, produce the desired quantities and deliver them to your facility on time.

With our private labeling solutions, you can maintain control of the entire process without having to manage any of the steps. Our focus on research and development, quality, and testing also ensures consistent products that meet your customers’ expectations, build brand loyalty and help your business grow and prosper.

Contact Blended Waxes Today to Learn More

Since 1976, Blended Waxes has created custom wax blends and other wax products for customers across many industries. Our services allow you to rely on our expertise and state-of-the-art equipment to make the products for your business.

For more information about our services and wax blends, please contact us by filling out the form on our website.